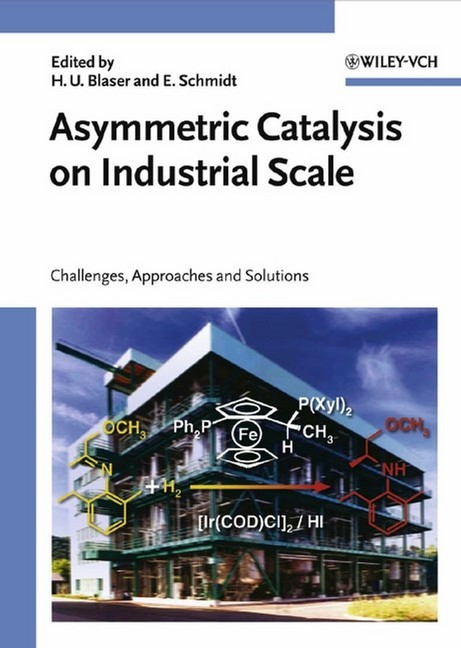

Asymmetric Catalysis on Industrial Scale

Challenges, Approaches and Solutions

Edited by two of the experts in the field, the central aim is to show organic chemists working in process development that enantioselective catalysis is suitable for the large-scale production of enantioenriched intermediates. In so doing, it is equally a source of information and inspiration for academic research, and, with its contribution by Noble prizewinner W. S. Knowles, will also heighten the status of industrial catalyst specialists working in the exciting field of enantioselective catalysis.

Some 25 contributions from top industrial researchers around the world present case studies on the development of the widest possible range of large-scale enantioselective processes, featuring stereoselective production processes of fine-chemicals, agrochemicals and pharmaceuticals. Clearly structured according to the nature of the task, this handbook adopts a problem-driven approach such that readers can easily find how colleagues have dealt with a similar situation.

Hans-Ulrich Blaser carried out this doctoral research with A. Eschenmoser at the Federal Institute of Technology (ETH) Zürich, from which he received the Ph.D. degree in 1971. Between 1971 and 1975 he held postdoctoral positions at the University of Chicago (J. Halpern), Harvard University (J.A. Osborn), and Monsanto (Zürich). During 20 years at Ciba0Geigy (1976-1996) he gained practical experience at R&D in the fine chemicals and pharmaceutical industry, which continued at Novartis (1996-1999) and at Solvias where he presently is chief technology officer. During his industrial career he has developed and implemented numerous catalytic routes for agrochemicals, pharmaceuticals and fine chemicals both as project leader and section head. His main interests are focused on (enantio) selective catalysis and the integration of catalytic steps into the syntheses of commercial products.

Some 25 contributions from top industrial researchers around the world present case studies on the development of the widest possible range of large-scale enantioselective processes, featuring stereoselective production processes of fine-chemicals, agrochemicals and pharmaceuticals. Clearly structured according to the nature of the task, this handbook adopts a problem-driven approach such that readers can easily find how colleagues have dealt with a similar situation.

Hans-Ulrich Blaser carried out this doctoral research with A. Eschenmoser at the Federal Institute of Technology (ETH) Zürich, from which he received the Ph.D. degree in 1971. Between 1971 and 1975 he held postdoctoral positions at the University of Chicago (J. Halpern), Harvard University (J.A. Osborn), and Monsanto (Zürich). During 20 years at Ciba0Geigy (1976-1996) he gained practical experience at R&D in the fine chemicals and pharmaceutical industry, which continued at Novartis (1996-1999) and at Solvias where he presently is chief technology officer. During his industrial career he has developed and implemented numerous catalytic routes for agrochemicals, pharmaceuticals and fine chemicals both as project leader and section head. His main interests are focused on (enantio) selective catalysis and the integration of catalytic steps into the syntheses of commercial products.

Elke Schmidt carried out her doctoral research with Prof. Christian Wandrey at the Institute for Biotechnology (Nuclear Research Center) in Juelich. She received her Ph.D. degree in 1987 from the Institute for Chemistry of the Rheinische Friedrich Wilhelm University, Bonn. During the last 16 years at Ciba-Geigy, Norvatis and Syngenta, she held various positions in R&D, during the last 10 years in Crop Protection Research.

Her main interest is focused on biotransformation, natural products discovery and fermentation development for small molecules and proteins.

1;Asymmetric Catalysis on Industrial Scale;3 1.1;Contents;7 1.2;List of Contributors;23 1.3;Introduction;29 1.3.1;1 Background and Motivation;29 1.3.2;2 Goals and Concept;29 1.3.3;3 Our (the Editors) Assessment of the Resulting Monograph;30 1.3.4;4 The Organization of the Book (Types of Intermediates - Catalysts - Situations);31 1.3.4.1;4.1 Category I: New Processes for Existing Active Compounds (Tab. 1);33 1.3.4.2;4.2 Category II: New Catalysts and/or Processes for Important Building Blocks (Tab. 2);33 1.3.4.3;4.3 Category III: Adaptation of Existing Catalysts for Important Building Blocks (Tab. 3);34 1.3.4.4;4.4 Category IV: Processes for New Chemical Entities (NCE) (Tab. 4);34 1.3.5;5 Missing Processes;34 1.3.6;6 Some Important Messages;37 1.3.6.1;6.1 Transformations and Catalyst Types;38 1.3.6.2;6.2 Scale, Development Stage;41 1.3.6.3;6.3 Synthesis Planning and Time Lines;41 1.3.6.4;6.4 Major Technical Problems;42 1.3.6.5;6.5 Technology and Patents;42 1.3.7;7 Final Comments and Conclusions;43 1.3.8;8 Glossary;44 1.3.9;9 References;46 1.4;I New Processes for Existing Active Compounds;49 1.4.1;1 Asymmetric Hydrogenations - The Monsanto L-Dopa Process;51 1.4.1.1;1.1 The Development of Chiral Phosphane Ligands [1];51 1.4.1.2;1.2 Synthesis and Properties of the Phosphanes;59 1.4.1.3;1.3 Mechanism of the Asymmetric Catalysis;63 1.4.1.4;1.4 Concluding Comments;65 1.4.1.5;1.5 Acknowledgements;66 1.4.1.6;1.6 References;66 1.4.2;2 The Other L-Dopa Process;67 1.4.2.1;2.1 Introduction;67 1.4.2.2;2.2 Choice of the Substrate;70 1.4.2.3;2.3 The Catalyst;72 1.4.2.4;2.4 Improving the Hydrogenation Reaction;73 1.4.2.5;2.5 Effect of Solvent and Anions;74 1.4.2.6;2.6 Immobilization of the Catalyst;77 1.4.2.7;2.7 Production Process;77 1.4.2.8;2.8 Acknowledgements;80 1.4.2.9;2.9 References;80 1.4.3;3 The Chiral Switch of Metolachlor: The Development of a Large-Scale Enantioselective Catalytic Process;83 1.4.3.1;3.1 Introduction and Problem Statement;83 1.4.3.2;3.2 Route Selection;84 1.4.3.2.1;3.2.1 Enamide Hydrogenation;84 1.4.3.2.2;3.2.2 Nucleophilic Substitution of an (R)-Methoxyisopropanol Derivative;85 1.4.3.2.3;3.2.3 Hydrogenation of MEA Imine;85 1.4.3.2.4;3.2.4 Catalytic Alkylation with Racemic Methoxyisopropanol;86 1.4.3.2.5;3.2.5 Assessment and Screening of the Proposed Routes;86 1.4.3.3;3.3 Imine Hydrogenation: Laboratory Process;87 1.4.3.3.1;3.3.1 Finding the Right Metal-Ligand Combination;87 1.4.3.3.1.1;3.3.1.1 Screening of Rh-Diphosphine Complexes;87 1.4.3.3.1.2;3.3.1.2 Screening of Ir-Diphosphine Complexes;88 1.4.3.3.1.3;3.3.1.3 Synthesis and Screening of a New Ligand Class;88 1.4.3.3.2;3.3.2 Optimization of Reaction Medium and Conditions;89 1.4.3.3.3;3.3.3 Ligand Fine Tuning;89 1.4.3.4;3.4 Imine Hydrogenation: Technical Process;90 1.4.3.4.1;3.4.1 Strategy for Process Development;90 1.4.3.4.2;3.4.2 The Production of the MEA Imine at the Required Quality;90 1.4.3.4.3;3.4.3 Scale-up of the Ligand Synthesis;91 1.4.3.4.4;3.4.4 Fine Optimization of the Ir-Catalyst Formulation;93 1.4.3.4.5;3.4.5 Choice of Reactor Technology;93 1.4.3.4.6;3.4.6 Scale-Up to the Production Autoclave;94 1.4.3.4.7;3.4.7 Work-up, Separation of the Catalyst from the Product;95 1.4.3.5;3.5 Summary and Conclusions;96 1.4.3.6;3.6 Acknowledgements;97 1.4.3.7;3.7 References;97 1.4.4;4 Enantioselective Hydrogenation: Towards a Large-Scale Total Synthesis of (R,R,R)-?-Tocopherol;99 1.4.4.1;4.1 Introduction: Vitamin E as the Target;99 1.4.4.2;4.2 Routes to (2R,4'R,8'R)-?-Tocopherol by Total Synthesis;102 1.4.4.3;4.3 Synthesis of Prochiral Allylic Alcohols;104 1.4.4.4;4.4 Asymmetric Hydrogenation of Prochiral Allylic Alcohols;106 1.4.4.5;4.5 Synthesis of the Diphosphane Ligands;109 1.4.4.6;4.6 Procedures for Stereochemical Analysis;112 1.4.4.7;4.7 Concluding Remarks;114 1.4.4.8;4.8 Acknowledgements;115 1.4.4.9;4.9 References;115 1.4.5;5 Comparison of Four Technical Syntheses of Ethyl (R)-2-Hydroxy-4-Phenylbutyrate;119 1.4.5.1;5.1 Introduction;119 1.4.5.2;5.2 Synthetic Pa

Blaser, Hans-Ulrich

Federsel, Hans-Jürgen

| ISBN | 9783527605774 |

|---|---|

| Artikelnummer | 9783527605774 |

| Medientyp | E-Book - PDF |

| Copyrightjahr | 2007 |

| Verlag | Wiley-VCH |

| Umfang | 480 Seiten |

| Sprache | Englisch |

| Kopierschutz | Adobe DRM |