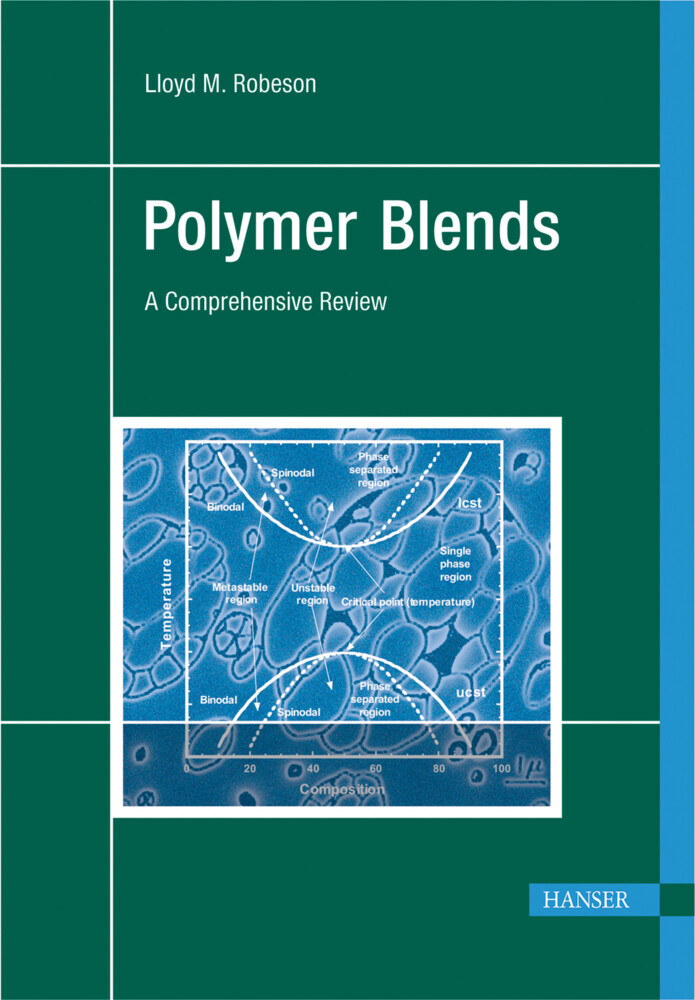

Polymer Blends

A Comprehensive Review

It has been well-recognized that polymer blends offer a key option in solving emerging application requirements. The ability to combine existing polymers into new compositions with commercializable properties offers the advantage of reduced research and development expense compared to the development of new monomers and polymers to yield a similar property profile. An additional advantage is the much lower capital expense involved with scale-up and commercialization. Another specific advantage of polymer blends versus new monomer/polymer compositions is that blends often offer property profile combinations not easily obtained with new polymeric structures. In the rapidly emerging technology landscape, polymer blend technology can quickly respond to developing needs.

This book offers a comprehensive overview of this important field, in particular a unique and extensive literature research on all aspects of this technology. It can be utilized as a reference text as well as a textbook for a graduate level course on polymer blends.

Contents:

Fundamentals of Polymer Blends

Compatibilization Methods for Polymer Blends

Types of Polymer Blends

Characterization of Polymer Blends

Properties of Polymer Blends

Commercial Applications of Polymer Blends

Future Perspectives in Polymer Blends

1;Preface;8

This book offers a comprehensive overview of this important field, in particular a unique and extensive literature research on all aspects of this technology. It can be utilized as a reference text as well as a textbook for a graduate level course on polymer blends.

Contents:

Fundamentals of Polymer Blends

Compatibilization Methods for Polymer Blends

Types of Polymer Blends

Characterization of Polymer Blends

Properties of Polymer Blends

Commercial Applications of Polymer Blends

Future Perspectives in Polymer Blends

1;Preface;82;Contents;103;1 Introduction;143.1;1.1 General Overview;143.2;1.2 Historical Review;163.3;1.3 Overviewof the Book;183.4;1.4 Definitions;193.5;References;204;2 Fundamentals of Polymer Blends;244.1;2.1 Thermodynamic Relationships;244.1.1;2.1.1 Combinatorial Entropy ofMixing;274.1.2;2.1.2 Enthalpy ofMixing;294.1.3;2.1.3 Flory-Huggins Theory;304.1.4;2.1.4 Equation of State Theories;324.2;2.2 Phase Behavior;374.2.1;2.2.1 Miscible versus Immiscible Blends;374.2.2;2.2.2 Spinodal Decomposition and Nucleation and Growth;404.3;2.3 Solubility Parameter Concepts;434.4;2.4 Specific Interactions;484.4.1;2.4.1 Hydrogen Bonding Interactions;484.4.2;2.4.2 Dipole-Dipole Interactions;534.4.3;2.4.3 Ion-Dipole and Ion-Ion Interactions;544.4.4;2.4.4 Additional Specific Interactions;554.5;2.5 Mean Field Theory and Intramolecular Repulsion Concepts;554.6;2.6 Association Model;614.7;2.7 Interfacial Aspects;624.8;2.8 AdditionalMethods of Predicting Polymer Phase Behavior;674.9;References;695;3 CompatibilizationMethods;785.1;3.1 Introduction of Specific Interacting Groups;795.2;3.2 In-Situ Polymerization Compatibilization;805.3;3.3 Ternary Polymer Addition (Nonreactive);835.4;3.4 Reactive Compatibilization;865.4.1;3.4.1 Reactive Extrusion Compatibilization (Single Pass Extrusion);945.5;3.5 Interpenetrating Polymer Networks;975.6;3.6 Crosslinking between Phases;1005.7;3.7 Block Copolymer Addition;1015.8;3.8 Polymer-Polymer Reactions;1055.9;3.9 AdditionalMethods of Compatibilization;1095.10;References;1116;4 Types of Polymer Blends;1226.1;4.1 Methods of Blend Preparation/Processing;1226.2;4.2 Elastomer Blends;1256.3;4.3 Elastomer (Low T)g-HighModulus (High Tg) Impact Modified Polymer Blends;1316.4;4.4 Polymer Blends Containing Crystalline Polymers;1376.4.1;4.4.1 Crystalline Polymer-Amorphous Polymer Blends;1376.4.2;4.4.2 Crystalline-CrystallinePolymer Blends;1436.4.3;4.4.3 Isomorphic Polymer Blends;1486.5;4.5 Polyolefin Blends;1506.6;4.6 Engineering Polymer Blends;1546.6.1;4.6.1 Poly(PhenyleneOxide) Based Blends;1546.6.2;4.6.2 Aromatic Polycarbonate Based Blends;1576.6.3;4.6.3 Polyarylate Based Blends;1606.6.4;4.6.4 Poly(Aryl Ether Ketone) Based Blends;1616.6.5;4.6.5 Aromatic PolysulfoneBased Blends;1636.6.6;4.6.6 Polyamide Based Blends;1636.6.7;4.6.7 Polyimide Based Polymer Blends;1646.6.8;4.6.8 Poly(Phenylene Sulfide) Based Blends;1666.6.9;4.6.9 Miscellaneous Engineering Polymer Blends;1666.7;4.7 Emulsion Blends;1676.8;4.8 Liquid Crystalline Polymer Blends and Molecular Composites;1726.8.1;4.8.1 Liquid Crystalline Polymer Blends;1726.8.2;4.8.2 Molecular Composites;1776.9;4.9 Polymer Blends Containing Block Copolymers;1796.10;4.10 Blends Based on Polystyrene and Styrene Copolymers;1856.11;4.11 Blends Based on PMMA and (Meth)Acrylate Copolymers;1926.12;4.12 Blends Based on PVC;1956.13;4.13 Blends Involving Thermosetting Polymers;2006.14;4.14 Water SolublePolymer Blends/PolyelectrolyteComplexes;2046.15;4.15 Biodegradable and Natural Polymer Based Blends;2116.15.1;4.15.1 Biodegradable Polymer Blends;2116.15.2;4.15.2 Natural Polymer Blends;2136.16;4.16 Miscellaneous Blends;2156.16.1;4.16.1 Recycled Polymer Blends;2156.16.2;4.16.2 Conductive Polymer Blends;2176.16.3;4.16.3 Ternary Polymer Blends;2206.16.4;4.16.4 Miscellaneous Polymer Blends;2226.17;4.17 Polymer Blend Composites;2236.18;References;2267;5 Characterization of Polymer Blends;2667.1;5.1 Glass Transition;2667.2;5.2 DynamicMechanical Characterization;2707.3;5.3 CalorimetricMethods;2757.4;5.4 Dielectric Characterization;2797.5;5.5 Morphology/Microscopy;2847.5.1;5.5.1 OpticalMicroscopy;2847.5.2;5.5.2 Transmission ElectronMicroscopy (TEM);2867.5.3;5.5.3 Scanning Electron Microscopy (SEM);2897.5.4;5.5.4 Atomic Force Microscopy (AFM);2917.5.5;5.5.5 Scanning TunnelingMicroscopy;2937.5.6;5.5.6 X-RayMicroscopy;2937.6;5.6 Scattering Methods: Light,X-Ray,Neutron;2937.6.1;5.6.1 Light Scattering;2957.6.2;5.6

1;Preface;8

2;Contents;10

3;1 Introduction;14

3.1;1.1 General Overview;14

3.2;1.2 Historical Review;16

3.3;1.3 Overviewof the Book;18

3.4;1.4 Definitions;19

3.5;References;20

4;2 Fundamentals of Polymer Blends;24

4.1;2.1 Thermodynamic Relationships;24

4.1.1;2.1.1 Combinatorial Entropy ofMixing;27

4.1.2;2.1.2 Enthalpy ofMixing;29

4.1.3;2.1.3 Flory-Huggins Theory;30

4.1.4;2.1.4 Equation of State Theories;32

4.2;2.2 Phase Behavior;37

4.2.1;2.2.1 Miscible versus Immiscible Blends;37

4.2.2;2.2.2 Spinodal Decomposition and Nucleation and Growth;40

4.3;2.3 Solubility Parameter Concepts;43

4.4;2.4 Specific Interactions;48

4.4.1;2.4.1 Hydrogen Bonding Interactions;48

4.4.2;2.4.2 Dipole-Dipole Interactions;53

4.4.3;2.4.3 Ion-Dipole and Ion-Ion Interactions;54

4.4.4;2.4.4 Additional Specific Interactions;55

4.5;2.5 Mean Field Theory and Intramolecular Repulsion Concepts;55

4.6;2.6 Association Model;61

4.7;2.7 Interfacial Aspects;62

4.8;2.8 AdditionalMethods of Predicting Polymer Phase Behavior;67

4.9;References;69

5;3 CompatibilizationMethods;78

5.1;3.1 Introduction of Specific Interacting Groups;79

5.2;3.2 In-Situ Polymerization Compatibilization;80

5.3;3.3 Ternary Polymer Addition (Nonreactive);83

5.4;3.4 Reactive Compatibilization;86

5.4.1;3.4.1 Reactive Extrusion Compatibilization (Single Pass Extrusion);94

5.5;3.5 Interpenetrating Polymer Networks;97

5.6;3.6 Crosslinking between Phases;100

5.7;3.7 Block Copolymer Addition;101

5.8;3.8 Polymer-Polymer Reactions;105

5.9;3.9 AdditionalMethods of Compatibilization;109

5.10;References;111

6;4 Types of Polymer Blends;122

6.1;4.1 Methods of Blend Preparation/Processing;122

6.2;4.2 Elastomer Blends;125

6.3;4.3 Elastomer (Low T)g-HighModulus (High Tg) Impact Modified Polymer Blends;131

6.4;4.4 Polymer Blends Containing Crystalline Polymers;137

6.4.1;4.4.1 Crystalline Polymer-Amorphous Polymer Blends;137

6.4.2;4.4.2 Crystalline-CrystallinePolymer Blends;143

6.4.3;4.4.3 Isomorphic Polymer Blends;148

6.5;4.5 Polyolefin Blends;150

6.6;4.6 Engineering Polymer Blends;154

6.6.1;4.6.1 Poly(PhenyleneOxide) Based Blends;154

6.6.2;4.6.2 Aromatic Polycarbonate Based Blends;157

6.6.3;4.6.3 Polyarylate Based Blends;160

6.6.4;4.6.4 Poly(Aryl Ether Ketone) Based Blends;161

6.6.5;4.6.5 Aromatic PolysulfoneBased Blends;163

6.6.6;4.6.6 Polyamide Based Blends;163

6.6.7;4.6.7 Polyimide Based Polymer Blends;164

6.6.8;4.6.8 Poly(Phenylene Sulfide) Based Blends;166

6.6.9;4.6.9 Miscellaneous Engineering Polymer Blends;166

6.7;4.7 Emulsion Blends;167

6.8;4.8 Liquid Crystalline Polymer Blends and Molecular Composites;172

6.8.1;4.8.1 Liquid Crystalline Polymer Blends;172

6.8.2;4.8.2 Molecular Composites;177

6.9;4.9 Polymer Blends Containing Block Copolymers;179

6.10;4.10 Blends Based on Polystyrene and Styrene Copolymers;185

6.11;4.11 Blends Based on PMMA and (Meth)Acrylate Copolymers;192

6.12;4.12 Blends Based on PVC;195

6.13;4.13 Blends Involving Thermosetting Polymers;200

6.14;4.14 Water SolublePolymer Blends/PolyelectrolyteComplexes;204

6.15;4.15 Biodegradable and Natural Polymer Based Blends;211

6.15.1;4.15.1 Biodegradable Polymer Blends;211

6.15.2;4.15.2 Natural Polymer Blends;213

6.16;4.16 Miscellaneous Blends;215

6.16.1;4.16.1 Recycled Polymer Blends;215

6.16.2;4.16.2 Conductive Polymer Blends;217

6.16.3;4.16.3 Ternary Polymer Blends;220

6.16.4;4.16.4 Miscellaneous Polymer Blends;222

6.17;4.17 Polymer Blend Composites;223

6.18;References;226

7;5 Characterization of Polymer Blends;266

7.1;5.1 Glass Transition;266

7.2;5.2 DynamicMechanical Characterization;270

7.3;5.3 CalorimetricMethods;275

7.4;5.4 Dielectric Characterization;279

7.5;5.5 Morphology/Microscopy;284

7.5.1;5.5.1 OpticalMicroscopy;284

7.5.2;5.5.2 Transmission ElectronMicroscopy (TEM);286

7.5.3;5.5.3 Scanning Electron Microscopy (SEM);289

7.5.4;5.5.4 Atomic Force Microscopy (AFM);291

7.5.5;5.5.5 Scanning TunnelingMicroscopy;293

7.5.6;5.5.6 X-RayMicroscopy;293

7.6

Robeson, Lloyd M.

| ISBN | 9783446436503 |

|---|---|

| Artikelnummer | 9783446436503 |

| Medientyp | E-Book - PDF |

| Copyrightjahr | 2013 |

| Verlag | Carl Hanser Verlag München |

| Umfang | 459 Seiten |

| Sprache | Englisch |

| Kopierschutz | Digitales Wasserzeichen |