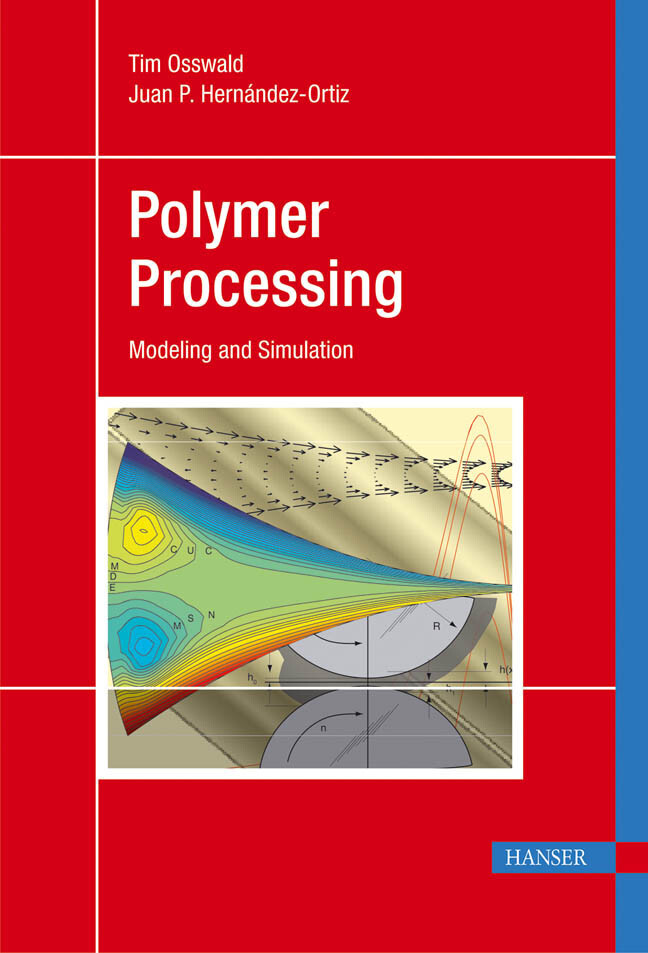

Polymer Processing

Modeling and Simulation

This book addresses traditional polymer processing as well as the emerging technologies associated with the plastics industry in the 21st Century, and combines engineering modeling aspects with computer simulation of realistic polymer processes. This book is designed to provide a polymer processing background to engineering students and practicing engineers. This three-part textbook is written for a two-semester polymer processing series in mechanical and chemical engineering. The first and second part of the book are designed for a senior- to graduate level course, introducing polymer processing, and the third part is for a graduate course on simulation in polymer processing. Throughout the book, many applications are presented in form of examples and illustrations. These will also serve the practicing engineer as a guide when determining important parameters and factors during the design process or when optimizing a process. Examples are presented throughout the book, and problems and solutions are available.

Contents:

- Introduction

- Part I - Background

Polymer Material Science, Processing Properties, Polymer Processes

- Part II - Processing Fundamentals

Dimensional Analysis and Scaling, Transport Phenomena in Polymer Processing, Analyses Based on Analytical Solutions

- Part III- Numerical Techniques

Introduction to Numerical Analysis, Finite Differences Method, Finite Element Method, Boundary Element Method, Radial Functions Method

Tim A. Osswald, Ph.D., is Kuo K. and Cindy F. Wang Professor at the University of Wisconsin-Madison College of Engineering and Honorary Professor of Plastics Technology at the University of Erlangen-Nuremberg and the National University of Colombia. He is the author of many books and book chapters, as well as over 100 papers in the field of plastics technology.

Contents:

- Introduction

- Part I - Background

Polymer Material Science, Processing Properties, Polymer Processes

- Part II - Processing Fundamentals

Dimensional Analysis and Scaling, Transport Phenomena in Polymer Processing, Analyses Based on Analytical Solutions

- Part III- Numerical Techniques

Introduction to Numerical Analysis, Finite Differences Method, Finite Element Method, Boundary Element Method, Radial Functions Method

Tim A. Osswald, Ph.D., is Kuo K. and Cindy F. Wang Professor at the University of Wisconsin-Madison College of Engineering and Honorary Professor of Plastics Technology at the University of Erlangen-Nuremberg and the National University of Colombia. He is the author of many books and book chapters, as well as over 100 papers in the field of plastics technology.

1;PREFACE;82;TABLE OF CONTENTS;103;INTRODUCTION;183.1;I.1 MODELING AND SIMULATION;183.2;I.2 MODELING PHILOSOPHY;213.3;I.3 NOTATION;253.4;I.4 CONCLUDING REMARKS;273.5;REFERENCES;284;PART I BACKGROUND;305;CHAPTER 1 POLYMER MATERIALS SCIENCE;325.1;1.1 CHEMICAL STRUCTURE;325.2;1.2 MOLECULAR WEIGHT;355.3;1.3 CONFORMATION AND CONFIGURATION OF POLYMER MOLECULES;405.4;1.4 MORPHOLOGICAL STRUCTURE;435.4.1;1.4.1 Copolymers and Polymer Blends;475.5;1.5 THERMAL TRANSITIONS;495.6;1.6 VISCOELASTIC BEHAVIOR OF POLYMERS;555.6.1;1.6.1 Stress Relaxation;555.6.2;1.6.2 Time-Temperature Superposition (WLF-Equation);575.7;1.7 EXAMPLES OF COMMON POLYMERS;605.7.1;1.7.1 Thermoplastics;605.7.2;1.7.2 Thermosetting Polymers;625.7.3;1.7.3 Elastomers;635.8;Problems;645.9;REFERENCES;676;CHAPTER 2 PROCESSING PROPERTIES;686.1;2.1 THERMAL PROPERTIES;686.1.1;2.1.1 Thermal Conductivity;696.1.2;2.1.2 Specific Heat;746.1.3;2.1.3 Density;766.1.4;2.1.4 Thermal Diffusivity;826.1.5;2.1.5 Linear Coefficient of Thermal Expansion;826.1.6;2.1.6 Thermal Penetration;846.1.7;2.1.7 Measuring Thermal Data;846.2;2.2 CURING PROPERTIES;906.3;2.3 RHEOLOGICAL PROPERTIES;946.3.1;2.3.1 Flow Phenomena;946.3.2;2.3.2 Viscous Flow Models;996.3.3;2.3.3 Viscoelastic Constitutive Models;1066.3.4;2.3.4 Rheometry;1166.3.5;2.3.5 Surface Tension;1216.4;2.4 PERMEABILITY PROPERTIES;1246.4.1;2.4.1 Sorption;1256.4.2;2.4.2 Diffusion and Permeation;1276.4.3;2.4.3 Measuring S, D, and P;1316.4.4;2.4.4 Diffusion of Polymer Molecules and Self-Diffusion;1336.5;2.5 FRICTION PROPERTIES;1336.6;Problems;1356.7;REFERENCES;1397;CHAPTER 3 POLYMER PROCESSES;1427.1;3.1 EXTRUSION;1437.1.1;3.1.1 The Plasticating Extruder;1447.1.2;3.1.2 Extrusion Dies;1537.2;3.2 MIXING PROCESSES;1567.2.1;3.2.1 Distributive Mixing;1597.2.2;3.2.2 Dispersive Mixing;1607.2.3;3.2.3 Mixing Devices;1627.3;3.3 INJECTION MOLDING;1717.3.1;3.3.1 The Injection Molding Cycle;1727.3.2;3.3.2 The Injection Molding Machine;1757.3.3;3.3.3 Related Injection Molding Processes;1807.4;3.4 SECONDARY SHAPING;1817.4.1;3.4.1 Fiber Spinning;1827.4.2;3.4.2 Film Production;1827.4.3;3.4.3 Thermoforming;1887.5;3.5 CALENDERING;1897.6;3.6 COATING;1917.7;3.7 COMPRESSION MOLDING;1947.8;3.8 FOAMING;1957.9;3.9 ROTATIONAL MOLDING;1977.10;REFERENCES;1988;PART II PROCESSING FUNDAMENTALS;2009;CHAPTER 4 DIMENSIONAL ANALYSIS AND SCALING;2029.1;4.1 DIMENSIONAL ANALYSIS;2039.2;4.2 DIMENSIONAL ANALYSIS BY MATRIX TRANSFORMATION;2059.3;4.3 PROBLEMS WITH NON-LINEAR MATERIAL PROPERTIES;2239.4;4.4 SCALING AND SIMILARITY;2239.5;Problems;2349.6;REFERENCES;23710;CHAPTER 5 TRANSPORT PHENOMENA IN POLYMER PROCESSING;23810.1;5.1 BALANCE EQUATIONS;23810.1.1;5.1.1 The Mass Balance or Continuity Equation;23910.1.2;5.1.2 The Material or Substantial Derivative;24010.1.3;5.1.3 The Momentum Balance or Equation of Motion;24110.1.4;5.1.4 The Energy Balance or Equation of Energy;24810.2;5.2 MODEL SIMPLIFICATION;25110.2.1;5.2.1 Reduction in Dimensionality;25310.2.2;5.2.2 Lubrication Approximation;25410.3;5.3 SIMPLE MODELS IN POLYMER PROCESSING;25610.3.1;5.3.1 Pressure Driven Flow of a Newtonian Fluid Through a Slit;25610.3.2;5.3.2 Flow of a Power Law Fluid in a Straight Circular Tube (Hagen-Poiseuille Equation);25810.3.3;5.3.3 Flow of a Power Law Fluid in a Slightly Tapered Tube;25910.3.4;5.3.4 Volumetric Flow Rate of a Power Law Fluid in Axial Annular Flow;26010.3.5;5.3.5 Radial Flow Between two Parallel Discs - Newtonian Model;26110.3.6;5.3.6 The Hele-Shaw model;26310.3.7;5.3.7 Cooling or Heating in Polymer Processing;27010.4;Problems;27410.5;REFERENCES;27611;CHAPTER 6 ANALYSES BASED ON ANALYTICAL SOLUTIONS;27811.1;6.1 SINGLE SCREW EXTRUSION-ISOTHERMAL FLOW PROBLEMS;27911.1.1;6.1.1 Newtonian Flow in the Metering Section of a Single Screw Extruder;28011.1.2;6.1.2 Cross Channel Flow in a Single Screw Extruder;28211.1.3;6.1.3 Newtonian Isothermal Screw and Die Characteristic Curves;28611.2;6.2 EXTRUSIO

Osswald, Tim A.

Hernandez-Ortiz, Juan P.

| ISBN | 9783446412866 |

|---|---|

| Artikelnummer | 9783446412866 |

| Medientyp | E-Book - PDF |

| Copyrightjahr | 2013 |

| Verlag | Carl Hanser Fachbuchverlag |

| Umfang | 633 Seiten |

| Sprache | Englisch |

| Kopierschutz | Digitales Wasserzeichen |